The Challenge: Labor vs. Capital

For many dairy farmers, the decision to switch to Automatic Milking Systems (AMS), or “milking robots,” is driven by a single, pressing reality: labor is hard to find and is getting more expensive.

However, trading human labor for capital investment is not a simple swap. While robots reduce the physical demand of milking, they introduce new costs—maintenance contracts, electricity, facility retrofits—and change the farm’s revenue structure through potential shifts in milk yield and feed costs.

To help producers navigate this complex financial decision, the Dairy Management program at UW-Madison has released the AMS Transition Budgeter. This web-based tool allows farmers to move beyond “back-of-the-napkin” math and visualize the long-term financial impact of retrofitting their farm for robotics.

How the tool works

The AMS Transition Budgeter is designed to answer three fundamental questions:

- What are the risks? It highlights how outcomes may shift if milk production changes or if interest rates rise.

- Is the transition profitable? It weighs labor savings and potential milk yield increases against new costs such as loan payments and maintenance.

- When will it pay off? The tool estimates how many years it will take for cash flow to turn positive.

The tool uses a standard partial budget. It doesn’t recalculate the entire farm’s finances; it only looks at what changes.

- Positive Changes (Credits): Value of labor hours saved + Value of increased milk yield.

- Negative Changes (Debits): Loan payments + Robot maintenance + Increased electricity + Feed cost adjustments (e.g., pellets).

Users enter their specific farm data: herd size, current labor costs, and estimated robot costs, and the tool instantly runs a 15-year simulation.

Case Study: The 120-Cow Family Farm

To illustrate the tool’s power, we applied it to a representative Wisconsin dairy farm.

The Scenario:

A farm milking 120 cows in a conventional parlor is considering installing 2 robotic units. The family and hired labor currently spend 12 hours a day on milking-related tasks. They pay an average labor rate (wages + benefits) of $20.00/hour.

The Investment:

- Robots: 2 units at $200,000 each ($400,000 total).

- Retrofit: $50,000 for barn modifications (guidance gates, office, milk lines).

- Financing: 10-year loan at 7.5% interest.

The Operational Assumptions:

- Milk Yield: Conservatively estimated to increase by 5% (from 80 to 84 lbs/cow) due to higher milking frequency.

- Labor: Reduced from 12 hours/day to 1.5 hours/day (0.75 hours/robot/day for fetching and cleaning).

- Feed Cost: Increasing by $0.15/cow/day to account for the pellet cost in the robot.

- Maintenance: $8,000 per robot/year.

Table 1: Input Summary (Parlor vs. AMS)

| Category | Current (Parlor) | Projected (AMS) |

|---|---|---|

| Milking Labor | 12.0 hours/day | 1.5 hours/day |

| Annual Labor Cost | $87,600 | $10,950 |

| Milk Production | 80 lbs/cow | 84 lbs/cow (+5%) |

| Capital Investment | $0 | $450,000 (Financed) |

| Maintenance | Minimal | $16,000 / year |

What the Tool Revealed

When we ran this scenario through the AMS Transition Budgeter, the tool produced a clear financial roadmap.

1. The Bottom Line: Profitable

The tool projected a Net Annual Impact of +$20,057.

Despite the significant new costs of the loan and maintenance, the savings in labor (approx. 3,800 hours/year) combined with the 5% milk yield increase were enough to offset the investment.

2. Cash Flow Projection

The tool maps cash flow over a 15-year horizon. In this case study, the cash flow remains positive from Year 1 because the operational savings immediately exceed the debt payments. However, users should note the sharp increase in profitability after Year 10, once the loan is fully paid off.

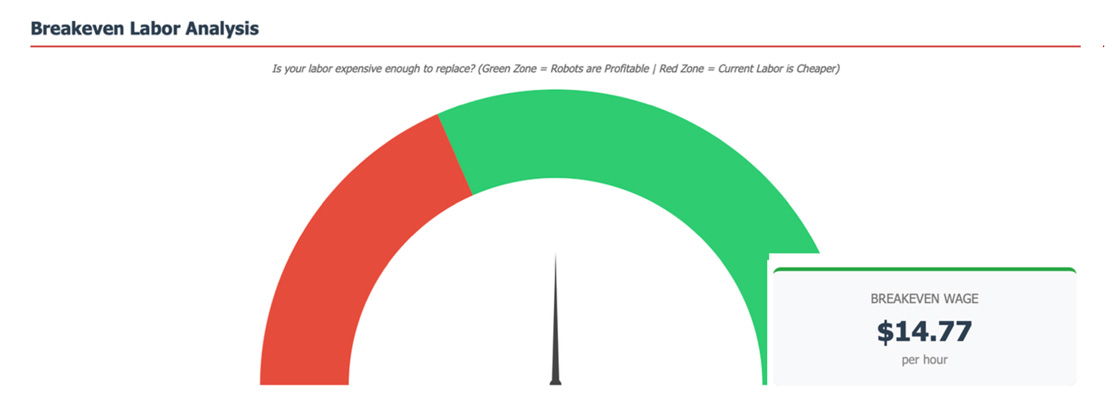

3. The “Breakeven Wage” Analysis

One of the tool’s most unique features is the “Breakeven Wage” Gauge. It answers the question: How expensive does my labor need to be to make robots worth it?

- The Result: The breakeven wage for this scenario was $14.77/hour.

- The Interpretation: Since the farm is currently paying $20.00/hour, the investment is financially sound. Essentially, the farm is replacing “expensive” human labor ($20.00) with a “cheaper” mechanized alternative (effective cost of $14.77).

- Rule of Thumb: If your actual labor cost is higher than the breakeven number, the transition is profitable.

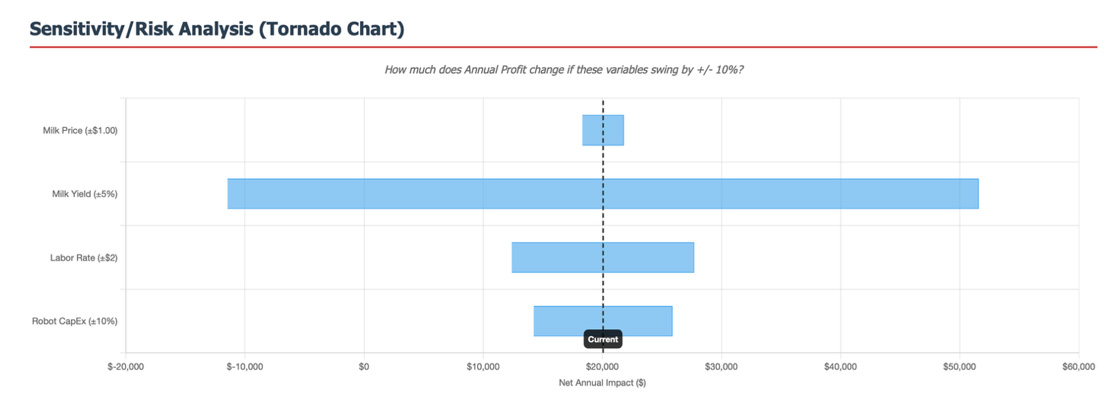

4. Risk Analysis

Using the tool’s sensitivity (Tornado chart), we identified that Milk Yield and Labor Rate were the two most sensitive variables. If the farm fails to achieve the 5% milk yield increase, the $20,000 annual profit could quickly vanish. This highlights that successful adoption is not just about buying the technology but managing the cows for production during the transition.

Take-Home Message

- It’s Not Just About Labor Cost: While high labor costs drive the decision, the profitability of robots often hinges on the milk yield response. If robots don’t increase production (via increased frequency), the math is much harder to justify.

- Know Your Breakeven: Every farm has a specific “Breakeven Labor Wage.” If you rely on cheap family labor, robots may not pay off financially—though they may still pay off in “quality of life,” which is a value this tool leaves for you to decide.

- Test Your Sensitivity: Don’t just run one scenario. Use the tool to ask: “What if milk prices drop?” or “What if I only get a 2% production increase?” The tool allows you to stress-test your business plan before signing the loan.

Access the Tool:

You can find additional technical details and use the AMS Transition Budgeter at:

https://dairymgt.cals.wisc.edu/tools.php ↗️ → FINANCIAL → AMS Transition Budgeter

https://dairymgt.cals.wisc.edu/tools/ams_budgeter/index.php ↗️

Author

Victor Cabrera

Dairy Systems Management Extension Specialist, Professor, Honorary Associate/Fellow– Dr. Cabrera uses applied research, interdisciplinary approaches, and participatory methods to deliver practical, user-friendly, and scholarly decision support tools for dairy farm management aimed to improve dairy farm profitability, environmental stewardship, and long-term sustainability of the dairy farm industry.

Published: February 5, 2026

Reviewed by:

- Carolina Pinzón, Dairy Outreach Specialist at the University of Wisconsin–Madison Division of Extension

- Katelyn Goldsmith, Dairy Outreach Specialist at the University of Wisconsin–Madison Division of Extension

Automated Milking Systems- Facility Design Considerations

Automated Milking Systems- Facility Design Considerations Managing Mastitis in Automatic Milking Systems (AMS)

Managing Mastitis in Automatic Milking Systems (AMS) Nutrition and Feeding Fundamentals in Automatic Milking Systems

Nutrition and Feeding Fundamentals in Automatic Milking Systems ▶️ Watch: Ask the Experts: Your Automatic Milking System Questions Answered

▶️ Watch: Ask the Experts: Your Automatic Milking System Questions Answered