Ruminants are built to eat quickly, so paying attention to what is going into their mouth will ensure they receive proper nutrition. Starch utilization is improved by making sure corn is broken down into smaller pieces, not just cracking the kernel into two pieces. The increased exposed surface area of the inner parts of the corn kernel allows the animal to get the most out of their corn silage feed since rumen bacteria have better access to the starch inside the corn kernels. The improved access to the starch is one reason it is so important to have proper corn processing.

The right time to check your kernel processing is when you can make adjustments and correct incomplete processing, during harvest. The method described below only requires a couple of simple tools, and is easy to do, even out in the field.

Materials Needed

What you need:

- Dishpan or 5-gallon bucket

- Water to fill dishpan (3/4 full) or

5-gallon bucket (1/2 full) - Cloth or paper towel

Getting Started

Fill your pan (3/4 full) or bucket (1/2 full) with water. Grab 2-3 representative handfuls of the harvested crop and add to the pan or bucket.

Next you will lightly submerge and stir the chopped forage. Ensure all pieces come in contact with the water, which allows the kernels to be separated from the stover. This is a quick process that should take under a minute for separation to occur.

Scoop out the stover that is floating on top of the water. You should be left with murky water and kernels of corn at the bottom of the pan or bucket. Carefully pour off the water, being careful to not dislodge the kernels at the bottom of the container.

Separating out corn kernels to determine adequacy of processing. Left: the harvested crop was just added to the dishpan, but have not yet been submerged. Middle: most of the stover has been scooped off the water. Right: water is being carefully poured off to ensure that none of the kernels are dislodged from the bottom of the dishpan.

Pour the kernels onto the cloth or towel and squeeze out any excess water. Spread the kernels out to evaluate size and amount of processing. Ideally, there should be very few whole or only cracked kernels. The majority of the kernels should be broken into several pieces.

Red circle-presence of whole kernels is not desirable. Yellow oval-kernel particles are adequately broken down.

For additional information on kernel processing evaluation, check out the Extension forage article that contains some tips and tricks to help you with challenges you may encounter with this process: view the article at: https://bit.ly/KernelProcessTips.

Going One Step Further

Another simple analysis that can be done to ensure optimal nutrition is to determine a corn silage processing score. This process determines particle processing using a series of sieves to separate out different size particles. The challenge with this process is that it does not allow you to make adjustments in the field during harvest because moisture content can affect results.

Particle size is important for two reasons:

- ensuring adequate coarse fiber to stimulate chewing and saliva production to buffer rumen pH.

- formation of the forage mat in the rumen which slows passage of feed through the digestive tract, giving microbes time to break down the feed.

Harvested material is added to the sieve box on top. Boxes are shaken according to a protocol. To see the complete protocol with the sieve shaker boxes, visit https://bit.ly/ParticleSepProtocol.

Right: Harvested forage material was added to the top box of the particle separator boxes. The boxes are shaken horizontally according to a protocol, then material from each layer is weighed individually to determine fraction percentages.

Once that step is completed, each fraction of silage that made it out of the top sieve and into the ones below are weighed individually. This allows you to determine the proportion falling through to the lower sieves. The goal is for most of the particles to end up in the middle two sieves, with fewer particles in the top sieve (coarse) and the bottom sieve (fine).

Left: Separated feed fractions after completing the shaker box separation.

Kernel processing scoring and silage processing scoring demonstrated by Matt Akins, UW–Madison Division of Extension Dairy Specialist.

Download Article

Basics of Cocktail Forage Mixes

Basics of Cocktail Forage Mixes Cocktail Forage Mix Yield, Quality, and Use in Lactating Cow Diets

Cocktail Forage Mix Yield, Quality, and Use in Lactating Cow Diets Dairy Cattle Ration Management During Summer

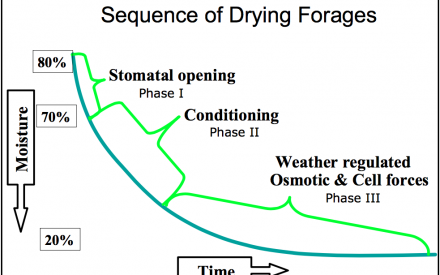

Dairy Cattle Ration Management During Summer Field Drying Forage for Hay and Haylage

Field Drying Forage for Hay and Haylage