How does forage dry?

If we understand and use the biology and physics of forage drying properly, not only does the hay dry faster and have less chance of being rained on, but the total digestible nutrients (TDN) of the harvested forage are higher. As mowing and conditioning equipment has evolved, some of the basic drying principles of forage have slipped by the wayside and we need to review them.

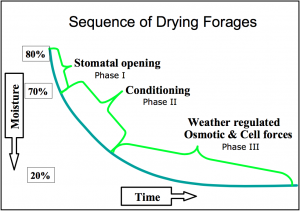

The general pattern of drying forages is shown in the figure at right. When forage is cut, it has 75 to 80 percent moisture, which must be dried down to 60 to 65% moisture content for haylage and down to 14 to 18% moisture content for hay (lower figures for larger bales).

The general pattern of drying forages is shown in the figure at right. When forage is cut, it has 75 to 80 percent moisture, which must be dried down to 60 to 65% moisture content for haylage and down to 14 to 18% moisture content for hay (lower figures for larger bales).

The first phase of drying is moisture loss from the leaves through the stomates. Stomates are the openings in the leaf surface that allow moisture loss to the air to cool the plant and carbon dioxide uptake from the air as the plant is growing. Stomates open in daylight and close when in dark. Cut forage laid in a wide swath maximizes the amount of forage exposed to sunlight, keeping the stomates open and encouraging rapid drying which is crucial immediately after cutting. Plant respiration continues after the plant is cut and gradually declines until plant moisture content has fallen below 60%. Therefore, rapid initial drying to lose the first 15% moisture will reduce loss of starches and sugars and preserve more dry matter and total digestible nutrients in the harvested forage. This initial moisture loss is not affected by conditioning.

The second phase of drying (II) is moisture loss from both the leaf surface (stomates have closed) and from the stem. At this stage conditioning can help increase drying rate. Conditioning to break stems every two inches allows more opportunities for water loss since little water loss will occur through the waxy cuticle of the stem.

The final phase of drying (III) is the loss of more tightly held water, particularly from the stems. Conditioning is critical to enhance drying during this phase.

How does swath width influence drying rate?

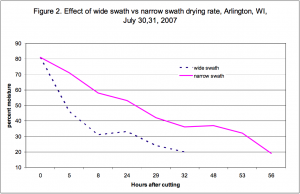

Using these principles will allow us to develop management practices in the field that maximize drying rate and TDN of the harvested forage. The first concept is that a wide swath immediately after cutting is the single most important factor maximizing initial drying rate and preserving of starches and sugars. In trials at the UW Arlington Research Station (Figure 2) where alfalfa was put into a wide swath, it reached 65% moisture in about 8 hours and could be harvested for haylage the same day as cutting. The same forage from the same fields put into a windrow was not ready to be harvested until the next day! Drying for hay was increased by one day.

Using these principles will allow us to develop management practices in the field that maximize drying rate and TDN of the harvested forage. The first concept is that a wide swath immediately after cutting is the single most important factor maximizing initial drying rate and preserving of starches and sugars. In trials at the UW Arlington Research Station (Figure 2) where alfalfa was put into a wide swath, it reached 65% moisture in about 8 hours and could be harvested for haylage the same day as cutting. The same forage from the same fields put into a windrow was not ready to be harvested until the next day! Drying for hay was increased by one day.

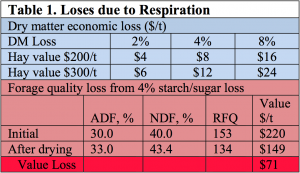

In fact, a wide swath is more important than conditioning for drying haylage. The value of rapid initial drying in a wide swath is shown in table 1.

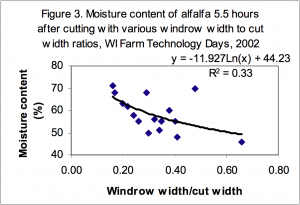

The importance of a wide swath is supported from drying measurements taken at the Wisconsin Farm Technology Days in 2002 (figure 3), where different mower-conditioners mowed and conditioned strips of alfalfa and put the cut forage in windrow widths of the operator’s choice. Moisture content of the alfalfa was measured 5.5 hours after mowing. Across all mower types and designs, the most significant factor in drying rate was the width of the windrow.

The importance of a wide swath is supported from drying measurements taken at the Wisconsin Farm Technology Days in 2002 (figure 3), where different mower-conditioners mowed and conditioned strips of alfalfa and put the cut forage in windrow widths of the operator’s choice. Moisture content of the alfalfa was measured 5.5 hours after mowing. Across all mower types and designs, the most significant factor in drying rate was the width of the windrow.

In figure 3, note the one outlying point at 70% moisture content and a windrow width/cut width ratio of 0.48. This shows how much drying can be slowed by improper adjustment of the conditioner.

In figure 3, note the one outlying point at 70% moisture content and a windrow width/cut width ratio of 0.48. This shows how much drying can be slowed by improper adjustment of the conditioner.

Many farmers have gradually gone to making windrows that are smaller percentages of the cut area as mowers have increased in size. Generally, as mowers have gotten bigger, the conditioner has stayed the same size, resulting in narrower windrows. There is some variation among makes and models and growers should look for those machines that make the widest swath.

Does swath width influence forage quality?

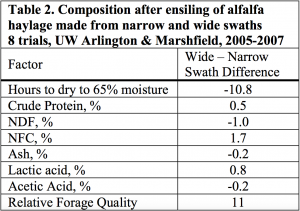

Putting alfalfa into wide swaths (72% of cut width) immediately after cutting, results in improved quality of alfalfa haylage compared to narrow windrows (25% of cut width) in studies at UW Arlington and Marshfield Research Stations in 2005 to 2007 (Table 2). Alfalfa was mowed with a discbine, conditioned, and forage was sampled approximately two months after ensiling in tubes. The alfalfa from the wide swaths had 1.0% less NDF, and 1.7% more NFC. Haylage from the wide swath had more substrate for fermentation, which resulted in more lactic and acetic acid. Higher acid content would indicate less rapid spoilage on feedout.

Putting alfalfa into wide swaths (72% of cut width) immediately after cutting, results in improved quality of alfalfa haylage compared to narrow windrows (25% of cut width) in studies at UW Arlington and Marshfield Research Stations in 2005 to 2007 (Table 2). Alfalfa was mowed with a discbine, conditioned, and forage was sampled approximately two months after ensiling in tubes. The alfalfa from the wide swaths had 1.0% less NDF, and 1.7% more NFC. Haylage from the wide swath had more substrate for fermentation, which resulted in more lactic and acetic acid. Higher acid content would indicate less rapid spoilage on feedout.

Some are concerned that driving over a swath will increase soil (ash) content in the forage. In table 1, the ash content of haylage from wide swath alfalfa was actually less than from narrow windrows. While narrow windrows are not usually driven over, they tend to sag to the ground causing soil to be included with the windrow when it is picked up. Wide swaths tend to remain on top of the cut stubble off the ground. Further, driving on the swath can be minimized by driving one wheel on the area between swaths and one near the middle of the swath where cut forage is thinner.

Grasses, especially if no stems are present, must be laid into a wide swath when cut. When put into a windrow at cutting, the forage will settle together, dry very slowly and be difficult to loosen up to increase drying rate.

Recommendations:

- Put cut forage into a wide swath at cutting that covers at least 70% of the cut area.

- For haylage: if drying conditions are good, rake multiple swaths into a windrow just before chopping (usually takes 5 to 7 hours after mowing).

- For hay: if drying conditions are good, merge/rake multiple swaths into windrow 12 to 24 hours after mowing (when forage is 40 to 60% moisture to avoid leaf loss).

For more information see Best Practices to Hasten Field Drying of Grasses and Alfalfa, A3927

Understanding Dry Matter: A Key to Better Dairy Feeding Management

Understanding Dry Matter: A Key to Better Dairy Feeding Management Check Your Corn Silage Processing During Harvest to Ensure Optimal Nutrition

Check Your Corn Silage Processing During Harvest to Ensure Optimal Nutrition ▶️ Watch: From Field to Feed: What We Know about Feeding High Oleic Soybeans

▶️ Watch: From Field to Feed: What We Know about Feeding High Oleic Soybeans ▶️ Watch: From Field to Feed: What We Know about Growing High Oleic Soybeans

▶️ Watch: From Field to Feed: What We Know about Growing High Oleic Soybeans