Listen to this article

Aerica Bjurstrom, Nesli Akdeniz and Heather Schlesser.

Introduction

In Wisconsin, farmers are experiencing greater challenges in ventilating their barns due to seasonal temperature changes and shifting wind patterns. Dairy farmers have traditionally relied on natural ventilation, where sidewall curtains and ridge vents drive air movement without the need for ventilation fans. While natural ventilation works well under moderate weather conditions, it often becomes inadequate during periods of heat stress, especially in newer barns with more than four rows of stalls. These conditions have led to a growing interest in mechanical ventilation systems, which can provide more consistent and controllable airflow inside dairy facilities.

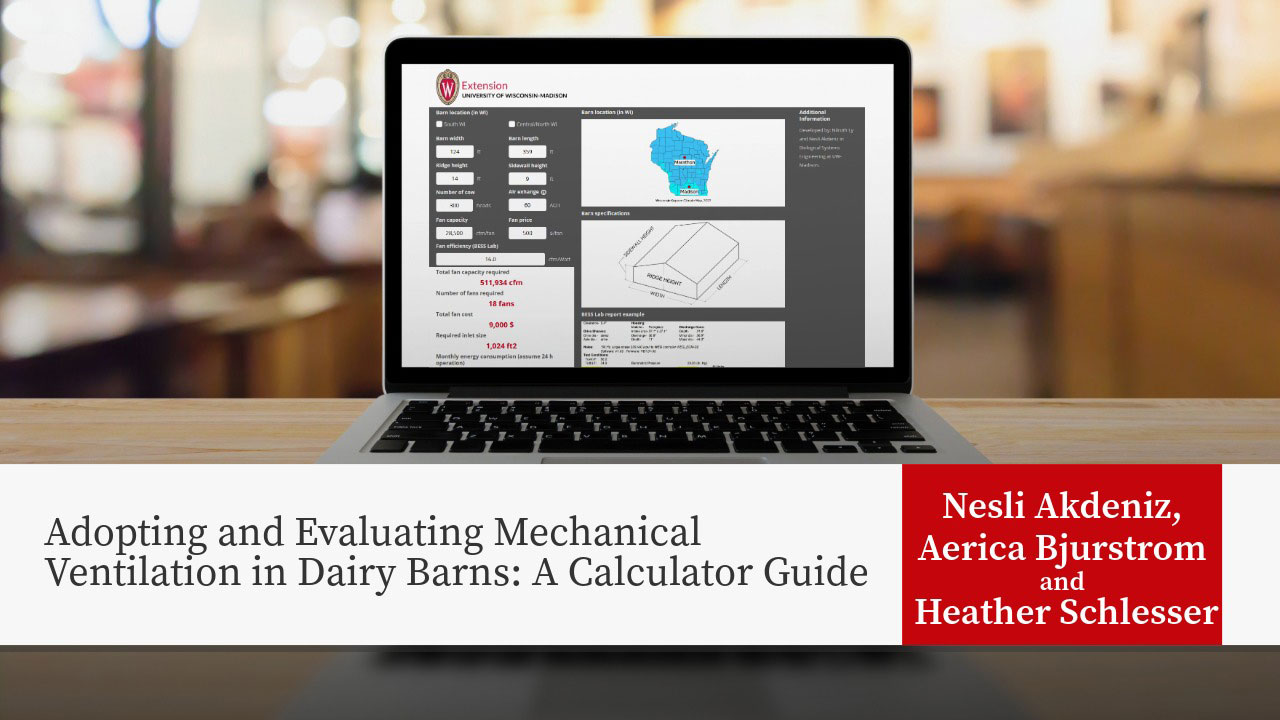

To support farmers in making informed decisions during this transition, we developed an online tool called the Cool Cows Calculator, available at go.wisc.edu/coolcows ↗️.

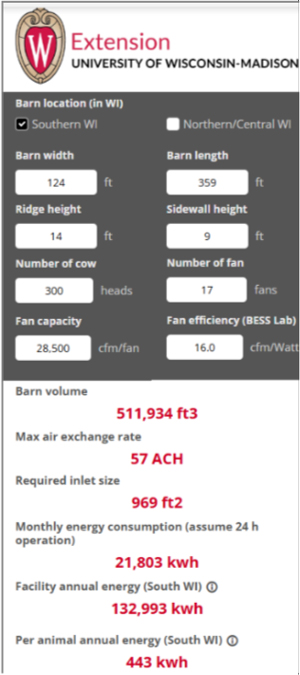

The calculator (Figure 1) helps plan and size a mechanical ventilation system that fits a facility’s specific needs. It estimates the number of fans required, the recommended air inlet size, and the expected energy consumption based on the facility’s layout and ventilation goals. The results can be used to compare different fan models or sizes and to evaluate potential energy savings before investing in equipment.

To use this calculator, users need to enter site-specific information, including the price and efficiency of the fans they plan to purchase. These can be obtained by visiting company websites or contacting manufacturers directly. Examples of ventilation fan companies (listed alphabetically) include Agromatic, J&D Manufacturing, Multifan/EMI, Norbco, SKOV-SECCO, VES-Artex, and ZIEHL-ABEGG.

Inputs

Barn location

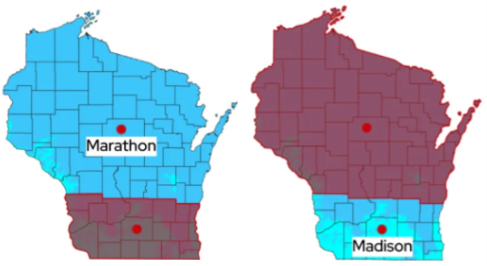

ince the weather patterns affect the ventilation requirements, the first step of using the calculator is to select a region. Once selected, an interactive map adjusts in color to reflect the chosen region (Figure 2).

Although Wisconsin can be divided into several climate regions, according to the Köppen climate classification, there are two main regions: the northern and central areas with relatively cooler summers, and southern Wisconsin with warmer and more humid summers.

Barn dimensions

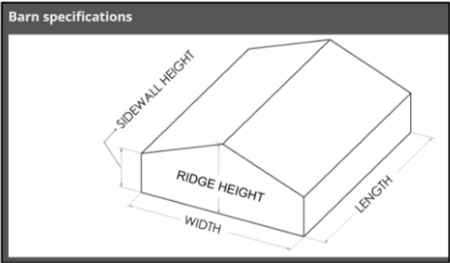

The barn dimensions include width, length, ridge height, and sidewall height, which define the volume of the barn, which is used to calculate air exchange rates. The barn dimensions figure can be checked to visualize each dimension (Figure 3).

Number of cows

The number of cows is also needed to estimate the ventilation requirements per animal. Please note that this calculator is based on the assumption that there is no overstocking. Overstocking can significantly affect ventilation needs.

Air exchange rate

The recommended air exchange rate for lactating cows is 60 air exchanges per hour during the summer months when ambient temperatures exceed 20°C. This number can be used in the calculations, or if a different air exchange rate is desired, it can be entered into the calculator. For example, if the ventilation system is designed for dry cows, the air exchange rate can be reduced to 40-50 air exchanges per hour.

Fan capacity

Fan capacity depends on fan size, which changes the total number of ventilation fans needed. Larger or high-capacity fans generally operate more efficiently. However, there needs to be a sufficient number of fans to distribute air evenly throughout the barn. For example, relying on only one or two very large fans would not provide enough coverage. Depending on the barn’s size, installing multiple fans is needed. The calculator allows users to enter different fan capacities to assess how each option affects the total number of fans required. While evaluating these options, it is also important to consider fan placement and whether adequate wall space is available for installation.

Fan price

Ventilation fan prices can vary widely. Please keep in mind that a lower-cost fan is not always the most economical option. A more expensive fan with higher efficiency may pay for itself within a few summers and provide savings over its expected 10-year lifespan.

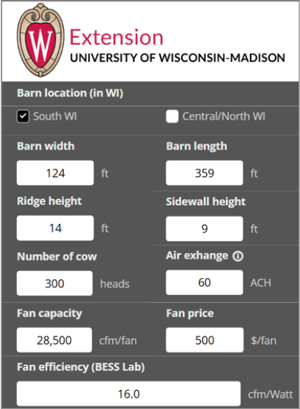

Fan efficiency

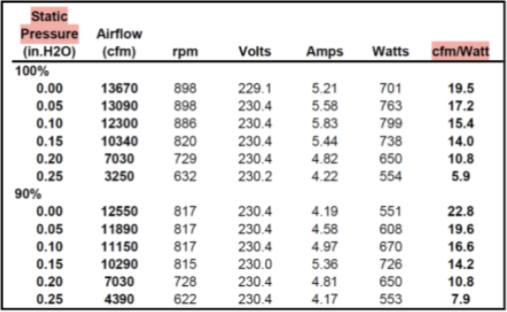

When purchasing a fan, one of the most important considerations is its efficiency, measured in cubic feet per minute per watt (cfm/Watt). The BESS Laboratory ↗️ at the University of Illinois at Urbana-Champaign is a certified laboratory that tests and reports fan performance (Figure 4). Anything inside a barn, such as cows, stalls, baffles, and milking robots, adds resistance to airflow and increases static pressure. Please request the BESS Laboratory test report from your provider to review fan performance at different static pressures. If a measured value for your barn is not available, a reasonable estimate for static pressure is 0.10 or 0.15 inches of water (in. H₂O).

Outputs

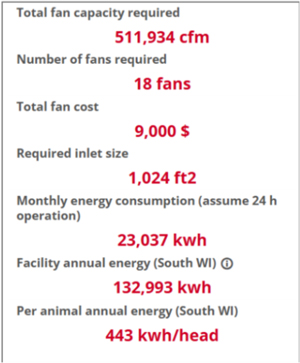

The Cool Cows Calculator determines the total fan capacity required to meet the ventilation goal, the number of fans needed, and the total system cost based on the fan price (Figure 5). It also calculates the required inlet size, which represents the open area necessary for fresh air to come in. An undersized inlet can increase static pressure and reduce fan efficiency.

The calculator provides monthly and annual energy consumption estimates based on continuous 24-hour fan operation, as well as the annual energy use per cow.

One advantage of the calculator is that inputs can be quickly adjusted to evaluate their effect on the results. For example, users can easily test how switching from a fan with 16 cfm/Watt efficiency to one with 18 cfm/Watt impacts annual energy consumption per cow. Even if higher-efficiency fans can initially be more expensive, the calculator helps estimate how many years it would take to recover the cost.

Evaluate mechanical ventilation

One of the limitations of the Cool Cows calculator is that it estimates annual energy consumption based on the assumption that exactly 60 air exchanges per hour can be achieved in summer (when ambient temperature exceeds 20°C). It also assumes four air exchanges per hour in winter (when the ambient temperature is below 4.4°C). While this represents a best-case scenario, in practice, achieving exactly 60 or 4 air exchanges per hour is often not possible. Even if variable-speed fans are used, actual air exchange rates may exceed or fall below the target.

To address this limitation, we modified the Cool Cows calculator. The second version of the calculator, which can be accessed at go.wisc.edu/coolcows2 ↗️ can be used to evaluate the performance of a mechanically ventilated system after it is designed. It can also be used to evaluate an existing mechanical ventilation system.

The Evaluating Calculator provides a similar but slightly different set of outputs focused on actual system performance (Figure 6). It reports the actual air exchange rate based on the fan capacity while confirming the required inlet size. It also estimates both monthly and annual energy use. These outputs help farmers assess the total energy consumed by their ventilation system, the energy use per cow, and whether upgrades or adjustments could improve system performance.

Authors

Neslihan Akdeniz

Livestock Controlled Environments Extension Specialist, Assistant Professor– Mainly focusing on controlled environments for livestock production, also interested in nutrient management and indoor plant-growing facilities.

Aerica Bjurstrom

Regional Dairy Educator – Aerica’s work focuses on herd health and animal welfare. She also has a strong background in meat quality and has done programming in market cow carcass quality.

Heather Schlesser

County Dairy Educator – Heather Schlesser is an Agriculture Educator in Marathon County. Heather’s research and outreach have included the use of current technology to enhance farm profitability and sustainability. Her current projects include the Animal Wellbeing Conference, the Midwest Manure Summit, Beef Quality Assurance, financial programming, and teaching farmers throughout the Midwest how to breed their own cattle.

References

- Akdeniz, N.; McCarville, J.; Schlesser, H.; Seefeldt, L.; Sterry, R. Ventilation in Dairy Buildings. Available online: https://dairy.extension.wisc.edu/articles/ventilation-in-dairy-buildings/ (accessed on 8/13/2025).

- Dairyland-Inititiative. Heat Abatement and Ventilation of Adult Cow Facilities. Available online: https://thedairylandinitiative.vetmed.wisc.edu/home/housing-module/adult-cow-housing/ventilation-and-heat-abatement/ (accessed on 8/13/2025).

- BESS-Lab. Agricultural Ventilation Fans, BioEnvironmental and Structural Systems Laboratory. Available online: http://bess.illinois.edu/pdf/12792.pdf (accessed on 8/13/2025).

- EIA-US. Electric Sales, Revenue, and Average Price, Commercial Average Monthly Bill by Census Division, and State. Available online: https://www.eia.gov/electricity/sales_revenue_price/ (accessed on 8/13/2025).

- Mondaca, M.R., Cook, N.B. 2019. Modeled construction and operating costs of different ventilation systems for lactating dairy cows. Journal of Dairy Science, 102: 896-908. https://doi.org/10.3168/jds.2018-14697