Introduction

Light plays a critical role in regulating cow behavior, milk production, and reproductive cycles. However, lighting is often overlooked in barn design and daily management despite its importance. Dairy barns in the Upper Midwest, including Wisconsin, Minnesota, Iowa, and Michigan, experience wide seasonal changes in natural daylight. To maintain consistent conditions throughout the year, farms in this region need to manage lighting to support cow health and productivity while minimizing energy use.

Long-Day Lighting for Lactating Cows

Long-day photoperiods (LDPP) consist of 16–18 hours of light at an intensity of 150–200 lux (15–20 foot candles), followed by 6–8 hours of darkness. This lighting approach has been shown to increase milk yield in lactating dairy cows by 5% to 15%. LDPP promotes higher feed intake and stimulates hormonal changes that support lactation, including increased levels of IGF-1 (Insulin-like Growth Factor 1) and prolactin while reducing melatonin secretion (Dahl et al., 2000). However, continuous 24-hour lighting does not further improve milk production and may negatively affect fertility, highlighting the need to maintain a dark daily period. Dairy farmers use timers to maintain long-day lighting during winter, while summer day lengths often naturally meet the target.

Short-Day Lighting for Dry Cows

Short-day lighting (8 hours of light, 16 hours of dark) is recommended for dry cows, aiding mammary gland development, which supports higher future milk yields . Once cows reach about 60 days before expected calving, cows are switched to a long-day photoperiod to stimulate lactation readiness (Lacasse et al., 2014).

Lighting types

LED lighting is energy-efficient, durable, and provides consistent light output. LED fixtures typically last 50,000 to 100,000 hours. Fluorescent lighting is generally cost-effective but less energy-efficient than LEDs, with a shorter lifespan of around 20,000 hours. High-intensity discharge (HID) includes metal halide and high-pressure sodium lamps. These are effective for lighting large areas but are energy-intensive and slow to reach full brightness (OMAFRA, 2020).

LED Lighting in Dairy Barns

The most common light that is used in dairy buildings is the light-emitting diode (LED). LED lights are either square-shaped and dimmable, with an angled roof to deter birds (AGM3 Peak Array), or rectangular-shaped with five bulbs, four of which could be turned off during nighttime.

Single-bulb LED lights or Fluorescent Lights in Dairy Barns

Single-bulb LED lights or fluorescent lights are also used in dairy buildings.

Metal Halide lights in Dairy Barns

In addition, metal halide lights are used to light some areas.

Regardless of the type used, light fixtures should be evenly spaced to maintain uniform lighting. Recommended fixture height varies but is typically placed at least 10–12 feet above the cows to minimize glare and shadows.

Site visits

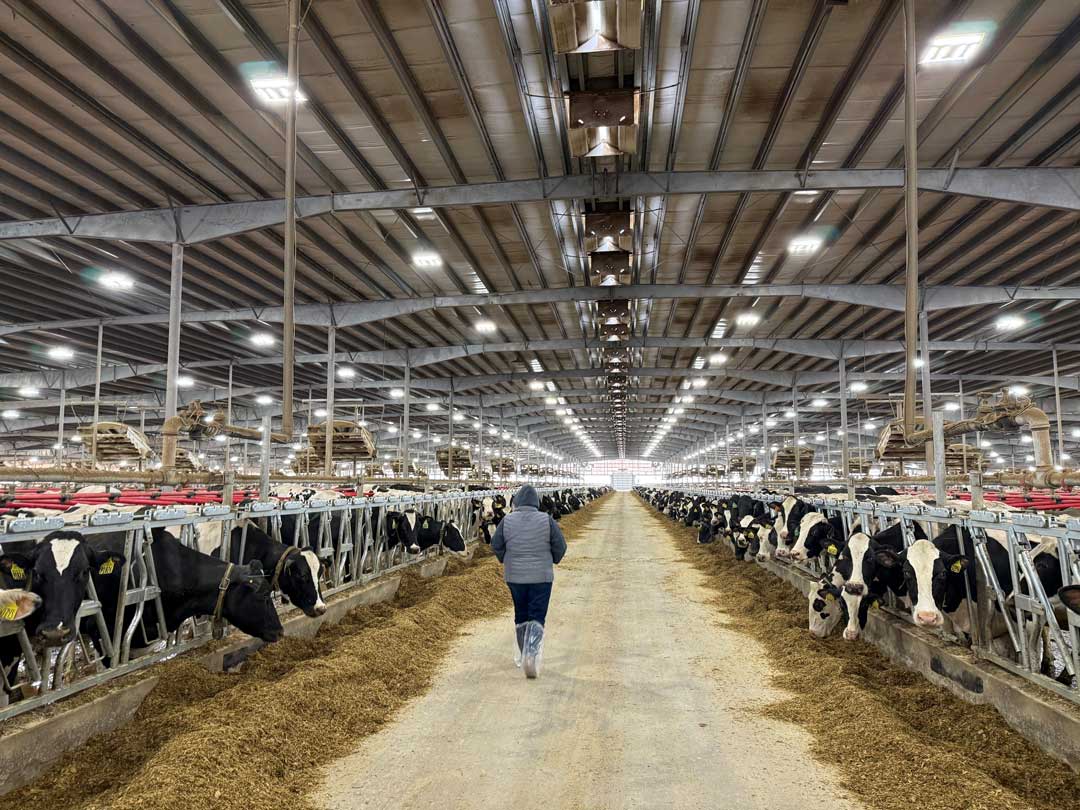

To measure light intensity, we visited seven dairy farms in Manitowoc County, Wisconsin, on a partly cloudy day with cloud cover ranging from 37 to 99% (Figure1).

Farm 1 was a new facility that was cross-ventilated and milked 5,500 cows three times daily.

Farm 2 was a tunnel-ventilated farm equipped with eight milking robots that milked approximately 440 cows.

Farm 3 was also a tunnel-ventilated farm and equipped with a robotic milking system. The building housed about 380 cows.

Farm 4 was a well-recognized farm with a commitment to sustainable farming practices. It had approximately 300 cows and a tunnel ventilation system.

Farm 5 housed about 1,300 lactating cows. We visited three buildings within this farm: a naturally ventilated dry cow building and two other tunnel-ventilated lactating cow buildings.

Farm 6 had a cross-ventilation system and baffles. It was a large state-of-the-art facility housing 3,300 cows.

Farm 7 had a tunnel ventilation system. We visited two buildings within Farm 7, each of which housed about 400 cows.

Figure 1. A snapshot of the lights, including natural lighting, used at each farm

Cross-ventilated barns did not have natural lighting other than the light coming from the air inlet. Natural and hybrid (tunnel) ventilated buildings received natural light along the length of the barn, primarily through ridge vents and, when transparent or open, through curtain sidewalls.

Light intensity measurements

An illuminance meter (Urceri MT-912) was used to measure the amount of light falling on a one-square-meter surface, expressed in lux (1 lux = 1 lumen per square meter).

Examples

| Surfaces illuminated by | Illuminance (lux) |

|---|---|

| Moonlight | ~0.2–1 lux |

| Office lighting | ~300–500 lux |

| Near windows or under skylights | ~10,000–25,000 lux |

| Direct sunlight | ~100,000 lux |

All buildings, except Farm 6, had a west-to-east orientation, with ventilation fans placed either on the east side (Farms 1, 4, 5, and 7) or the west side (Farms 2 and 3). Farm 6 had a north-to-south orientation, with ventilation fans on the south end and an air inlet on the north side. In west–east oriented barns, light intensity was measured approximately every three meters along the length of the barn at cow eye level. On Farm 6, measurements were taken along both the length and width of the barn.

While hybrid ventilated buildings with ridge vents received plenty of natural light, artificial lights were needed for cross-ventilated buildings.

Light intensity

Figure 2 presents the measured light intensity (in lux) inside the dairy buildings using either natural/hybrid or cross-ventilation systems. The figure shows clear differences in light levels depending on the ventilation design. Dairy buildings with natural or hybrid ventilation (indicated in blue) exhibited higher light intensities compared to cross-ventilated buildings (orange) because ridge vents and open roof design allowed more daylight to enter.

Among naturally ventilated farms, Farm 3 and Barn 1 at Farm 5 showed the highest average light intensities, both exceeding 1,200 lux, suggesting access to natural daylight. The light intensity at Farm 4 was lower compared to other naturally ventilated facilities, primarily because only single LED lights were used at this site. However, measured values still exceeded the recommended 150–200 lux threshold, indicating that the lighting was adequate to meet the minimum requirements for lactating cows.

Cross-ventilated barns, including Farm 1 and both orientations at Farm 6 (N-S and W-E), showed lower light intensities, all falling under 400 lux, which reflects their more enclosed design that limits daylight penetration. At Farm 6, airflow was directed from north to south, with ventilation fans on the south wall. Light intensity dropped below the 150 lux threshold along the west-east side of the barn. Upgrading the lighting system or adding additional fixtures may be worthwhile for this farm.

Overall, the data suggested that naturally or hybrid ventilated barns provide better natural lighting conditions, contributing to energy savings by reducing the need for artificial lighting. Given that Wisconsin experiences sunny or partly sunny conditions for nearly half the year, ranging from 185 to 190 days (CurrentResults, 2025), installing skylights or transparent sidewalls and keeping them clean can significantly reduce energy use.

A previous study found that approximately 47 percent of on-farm electricity use was dedicated to milking (Figure 3). Another 46 percent was used for lighting and ventilation, while the remaining 7 percent covered feeding and manure handling. Milk cooling accounted for the largest share at 25 percent, while lighting was surprisingly the second highest, using 17 percent of electricity in tie-stall barns and 26 percent in free-stall barns (Sanford, 2010).

Summary

Although mechanical ventilation use has increased significantly in recent years, shifting the proportions of electricity use, managing energy costs remains essential, especially considering milk margins continue to vary from year to year. Using a low-cost light meter to monitor indoor light levels throughout the year can help optimize lighting schedules and enhance overall energy efficiency.

Authors

Neslihan Akdeniz

Livestock Controlled Environments Extension Specialist, Assistant Professor– Mainly focusing on controlled environments for livestock production, also interested in nutrient management and indoor plant-growing facilities.

Angie Ulness

Dairy Educator – Angie has been active in the dairy industry her entire life. She was raised on her family farm in Door County and currently farms with her husband Mark and their four children in Manitowoc County. Angie has previously worked as a Field Representative for Holstein USA and a Senior Territory Manager for a Pharmaceutical company. Her area of focus is Dairy Farm Management, Profitability and Efficiency.

Acknowledgement

We greatly acknowledge Manitowoc County dairy producers for allowing us to visit and collect data for this study.

References

- Current Results. (2025). Average sunshine in Madison, Wisconsin (sunny and partly sunny days). https://www.currentresults.com/Weather/Wisconsin/annual-days-of-sunshine.php (access date 5-21-2025).

- Dahl, G.E., Buchanan, B.A., Tucker, H.A. 2000. Photoperiodic effects on dairy cattle: A review. Journal of Dairy Science: https://doi.org/10.3168/jds.S0022-0302(00)74952-6.

- Lacasses, P., Vinet, C.M., Petitclerc, D. 2014. Effects of prepartum photoperiod and melatonin feeding on milk production and prolactin concentration in dairy heifers and cows. Journal of Dairy Science: https://doi.org/10.3168/jds.2013-7615.

- Sanford, S. 2010. Dairy Farms, University of Wisconsin-Madison. https://fyi.extension.wisc.edu/energy/dairy-farms/ (access date 5-21-2025).

- OMAFRA (Ontario Ministry of Agriculture, Food and Rural Affairs), 2020. Lighting options for free stall housing. https://www.ontario.ca/page/lighting-options-free-stall-housing (access date 5-21-2025).