English | Español

Introduction

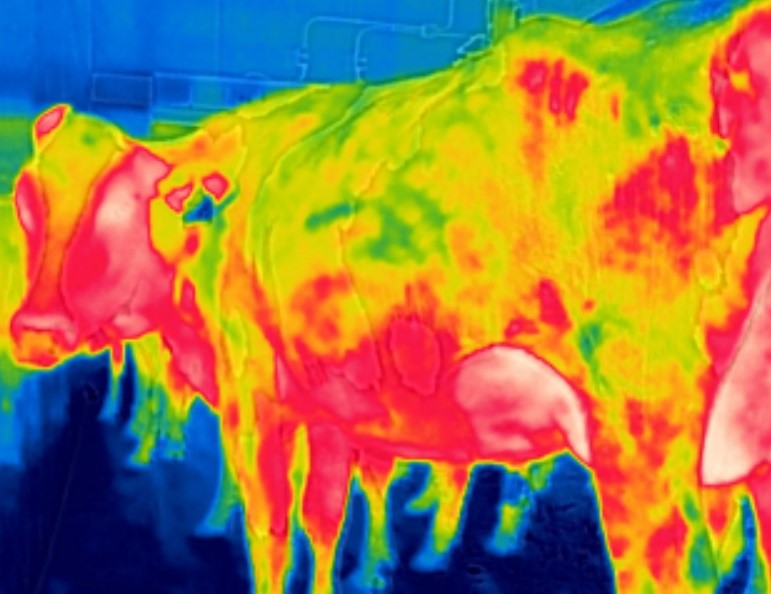

Hot weather can bring a long list of problems for dairy producers. When cows are heat stressed, they eat less, produce less milk, have reduced immune function and higher SCC, and show reduced fertility. A spike in lameness often follows the hot season. In severe heat waves, cows can even die. In addition to the economic burden, the discomfort from heat stress also reduces animal welfare.

This article focuses primarily on cooling cows housed in barns, where they are shaded to prevent heat gain from direct sun exposure. For information specific to pasture and grazing systems, see Dealing with Hot Weather in Pasture/Grazing Systems.

Do Your Cows Need Help Coping?

Consequences of heat stress, such as a drop in feed intake and milk production, are delayed from when cows begin to experience discomfort. By the time you notice a change in milk yield, the problem may have been ongoing for at least a day or more.

To stay ahead of severe problems, we can look for other signs to tell us whether cows are coping well with heat stress, or if facilities need to be modified to provide better heat abatement. Environmental factors, such as air temperature, relative humidity, or Temperature Humidity Index (THI), can only tell us so much. The best strategy for troubleshooting heat stress on each unique farm is to observe how the cows are responding.

The following signs are some natural coping mechanisms cows use to try to lose heat and maintain a normal core body temperature. Often, these natural mechanisms are inadequate and cows need a hand from additional heat abatement in their facilities.

A clear indicator of severe heat stress is panting. Look for any cows breathing with their mouths wide open, tongues out, stringy drool hanging down, or a combination of these signs (Figure 1).

Before severe panting occurs, cows will show increased respiration (breathing) rates. A rule of thumb is 60 breaths per minute or 1 breath per second. When at least a quarter of the cows in a pen are breathing that quickly or faster, they are struggling to cope adequately with the heat and additional cooling would be beneficial.

(Photo credit: Jennifer Van Os)

When cows breathe faster, pant, and sweat, they lose moisture. This must be replenished by increasing their water intake. A sign that cows are hot is not just drinking more water, but also bunching around the water trough without drinking.

Additionally, cows may bunch away from the side and end walls of the barn. This behavior reflects shade seeking, as cows associate bright light intensity with heat.

In addition, cows will eat less, particularly during hot times of the day. If soakers are mounted over the feed bunk, cows will seek out the cooling effect and spend more time there both eating and standing without eating. The soakers help lower their core body temperature and improve feed intake and milk yield. However, the increased standing time can raise the risk for lameness.

Regardless of whether soakers are available, heat stressed cows spend more time standing up and less time lying down. While lying down, their core body temperature rises. Standing helps them dissipate heat and lower their body temperature. Based on this behavior, a higher proportion of cows standing is yet another indicator of heat stress.

This is why it is important to make sure there is sufficient, consistent, fast-moving air over the stalls or bedded pack. It is critical for the air to reach the cows and help them dissipate heat in the place where they should be spending over half their day lying down.

Air Exchange and Air Movement

Barn ventilation systems serve two important functions for heat abatement: air exchange and fast air movement.

Ventilation technically refers to air exchange, meaning bringing fresh air into the barn and removing warm, humid air, including noxious gases such as ammonia. This exchange of stale and fresh air is important for both heat abatement and promoting respiratory health in cattle and people working in the barns. In the summer, the target air exchange rate is 40-60 air changes per hour, whereas in the winter, 4-8 air changes per hour can suffice.

In addition, ventilation systems serve an important function for summer heat abatement by providing fast- moving air on the cows, helping them dissipate heat. This fast-moving air is beneficial for cows in many locations, including the holding pen, the parlor, at the feed bunk, and in the lying area.

An important outcome for cow comfort is sufficient resting time. Cows need to spend at least half of their day lying down, so high air speeds are essential over the stalls or bedded pack. A target of no less than 200 feet per minute (2.3 mph), but ideally 400 feet per minute (4.6 mph) should reach down to a height of 20-30” above the stall base. These high air speeds should be consistent among the stalls in a pen or throughout the resting area. Otherwise, some cows, usually the less dominant ones, will have less access to adequate cooling. Air speeds can be measured using a hand-held device called an anemometer, such as those sold by Kestrel. ↗️

To get a good “bang” for your cooling “buck,” the holding area represents an opportunity to turn an area that could cause heat stress into a cost-efficient location to cool cows. Holding areas often have inadequate natural ventilation. Although many are equipped with recirculation fans to direct high velocity air onto the cows, the air can become increasingly hot and humid when it gets recycled within the space. Fast-moving air should be combined with soaker systems to maximize cooling during a cow’s time in the holding area. To promote effective heat loss, including exposing the body surface area available for cooling, tight bunching of cows in the holding pen should be minimized. Bringing groups of cows in a staggered manner can help provide the necessary space, especially during extreme heat events.

Naturally vs. Mechanically Ventilated Barns

Naturally ventilated barns can be cost effective for taking advantage of prevailing winds. In stalls located near the air inlet at the curtains, high air speeds can sometimes be achieved passively. To ensure fast-moving air reaches all the stalls at the proper height, installing fans over the stalls can be beneficial (Figure 2). Fans can be highly effective but must be spaced closely enough and angled correctly to ensure the fast-moving air reaches cows in all stalls.

(Photo courtesy of The Dairyland Initiative)

For some dairy operations, barns may have site challenges such as multiple buildings close together, blocking natural wind. For this and other situations, mechanically ventilated barns can promote air exchange by forcing air to travel through the barn using inlets, outlets, and exhaust fans. Mechanical barns include negative pressure systems where fans pull air out of the barn or positive pressure systems where fans push air into the barn. Negative pressure mechanical barns include tunnel barns, where air enters and exits from the short sides of the barns and flows parallel to the feed bunk, or cross-ventilated barns, where air travels perpendicular to the feed bunks.

To ensure proper fast-moving air at the cows’ standing and lying heights, these barns may use various additional features such as baffles to passively push air downward at specific locations (Figure 3), low flat ceilings to keep the moving air at cow height throughout the barn, or fans above the stalls to force a jet of air over the cows.

(Photo courtesy of The Dairyland Initiative)

For details on barn ventilation design recommendations, see The Dairyland Initiative. ↗️

Water Soakers

Water-based cooling can take two main forms: misting vs. soaking. High-pressure misting or fogging injects the air with very fine droplets to lower the temperature surrounding the cows. At the same time, this results in an increase in relative humidity. Therefore, this strategy works best in drier climates like the southwestern U.S.

In contrast, low-pressure soakers, sprinklers, or showers deliver coarser droplets to wet cows directly. Energy from the cows’ body heat evaporates the water, cooling them. The water also draws heat away from the cows’ skin directly. These processes do not depend on relative humidity, so soaking works across a range of climates and regions. The cooling effects of soakers are enhanced when combined with fast-moving air from fans. In addition, the evaporating droplets also cool the air, just like with misters or foggers.

(Photo credit: Jennifer Van Os)

Soaking has been shown to be very effective for reducing respiration rate and body temperature, and for increasing feeding time, feed intake, and milk yield. Similar principles apply whether soaking cows at the feed bunk in their home pen, in the holding pen, in the parlor itself, or at the exit lane.

On average, milk production decreases sharply when the THI reaches 68 to 72. This translates to about 70 to 75°F in a humid continental climate like in much of the Midwest or Northeast. Consider activating soakers starting at 70°F or even 65°F to help cows beat the heat. Nozzles should deliver approximately 1 gallon per spray application over the course of 3 minutes or less. At the feed bunk, each nozzle can cool at least 2-3 adjacent cows. The spray should activate every 15 minutes or more frequently, especially in hotter weather when evaporation is quicker.

All Age Groups Benefit from Cooling

Lactating cows produce twice the amount of metabolic heat that non-lactating animals do, which makes them particularly sensitive to the heat. Nonetheless, heat stress affects cattle of all ages.

When dry cows are heat stressed, not only is their welfare and future productivity affected, but also the developing fetus they carry. Calves born from heat-stressed dams have reduced health, survival, and performance. Calves and growing heifers benefit from heat abatement, similar to adult dry and lactating cows.

Providing shade or shelter to all age groups, including dry cows and youngstock, is a basic expectation for animal welfare. Checking that all animals have access to shelter is part of many welfare audits or evaluations. Shade can be in the form of either permanent or temporary structures. When positioning a shade structure, its orientation should be north-to-south on the long side. The shadow will move throughout the day as the sun moves across the sky, and cattle will follow the shadow. This will result in the area directly under the shade structure remaining a drier and cleaner place for cattle to rest. The distance the shadow moves is proportional to the structure’s height, so a taller structure will promote more frequent animal movement.

For more information on cooling dry cows, see Dry Cow Heat Stress Management.

For more information on cooling calves, see Heat Abatement Strategies for Calves.

Authors

Jennifer Van Os

Associate Professor and Extension Specialist in Animal Welfare – Jennifer Van Os is an Associate Professor and Extension Specialist in Animal Welfare in the Department of Animal & Dairy Sciences at UW-Madison. She conducts applied research and extension to help dairy farmers improve the welfare of their animals using science-based animal care practices.

Courtney Halbach

Outreach Specialist for The Dairyland Initiative – Courtney’s areas of interest include calf and adult cow barn design, positive pressure tube ventilation systems, and automatic milking facility design.

Carolina Pinzón-Sánchez

Bilingual Dairy Outreach Specialist – As a statewide Dairy Outreach Specialist, Carolina identifies needs and incorporates research findings into high-quality outreach education programs around dairy production.

Original Authors

Jennifer Van Os and Theodore Halbach.

Original publication date: July, 2020

Revised: July, 2025

References

- Allen, J. D., L. W. Hall, R. J. Collier, and J. F. Smith. 2015. Effect of core body temperature, time of day, and climate conditions on behavioral patterns of lactating dairy cows experiencing mild to moderate heat stress. J. Dairy Sci. 98:118-127.

- Atkins I. K., N. B. Cook, M. R. Mondaca, and C. Y. Choi. 2018. Continuous respiration rate measurement of heat-stressed dairy cows and relation to environment, body temperature, and lying time. Trans ASABE 61:1475-1485.

- Berman, A. 2005. Estimates of heat stress relief needs for Holstein dairy cows. J. Anim. Sci. 83:1377-1384.

- Berman, A. 2008. Increasing heat stress relief produced by coupled coat wetting and forced ventilation. J. Dairy Sci. 91:4571-4578.

- Bernabucci, U., N. Lacetera, L. H. Baumgard, R. P. Rhoads, B. Ronchi, and A. Nardone. 2010. Metabolic and hormonal acclimation to heat stress in domesticated ruminants. Animal 4:1167-1183

- Bianca, W. 1968. Thermoregulation. In: Adaptation of domestic animals, ed. E. S. E. Hafez. Lea & Febiger, Philadelphia, PA.

- Chen, J. M., K. E. Schütz, and C. B. Tucker. 2013. Dairy cows use and prefer feed bunks fitted with sprinklers. J. Dairy Sci. 96:5035-5045.

- Chen, J. M., K. E. Schütz, and C. B. Tucker. 2015. Cooling cows efficiently with sprinklers: Physiological responses to water spray. J. Dairy Sci. 98:6925-6938.

- Chen, J. M., K. E. Schütz, and C. B. Tucker. 2016a. Cooling cows efficiently with water spray: Behavioral, physiological, and production responses to sprinklers at the feed bunk. J. Dairy Sci. 99:4607-4618.

- Chen, J. M., K. E. Schütz, and C. B. Tucker. 2016b. Sprinkler flow rate affects dairy cattle preferences, heat load, and insect deterrence behavior. Appl. Anim. Behav. Sci. 182:1-8.

- Cook, N. B., J. P. Hess, M. R. Foy, T. B. Bennett, and R. L. Brotzman. 2016. Management characteristics, lameness, and body injuries of dairy cattle housed in high-performance dairy herds in Wisconsin. J. Dairy Sci. 99:5879-5891.

- Cook, N. B., R. L. Mentink, T. B. Bennett, and K. Burgi. 2007. The effect of heat stress and lameness on time budgets of lactating dairy cows. J. Dairy Sci. 90:1674-1682.

- Cook, N. B. and K. V. Nordlund. 2009. The influence of the environment on dairy cow behavior, claw health and herd lameness dynamics. Vet. J. 179:360-369.

- Dahl, G. E., S. Tao, and A. P. A. Monteiro. 2016. Effects of late-gestation heat stress on immunity and performance of calves. J. Dairy Sci. 99:3193-3198.

- The Dairyland Initiative. 2020. https://thedairylandinitiative.vetmed.wisc.edu/home/housing- module/adult-cow-housing/ventilation-and-heat-abatement/

- De Rensis, F. and R. J. Scaramuzzi. 2003. Heat stress and seasonal effects on reproduction in the dairy cow: A review. Theriogenology 60:1139-1151.

- Farmers Assuring Responsible Management (FARM). 2020. Animal Care Reference Manual – Version 4.0 Abbreviated. https://nationaldairyfarm.com/wp-content/uploads/2020/02/Animal-Care-V4-Manual- Print-Friendly.pdf ( https: /nationaldairyfarm.com/wp-content/uploads/2020/02/Animal-Care-V4-Manual-Print- Friendly.pdf ) .

- Ferreira, F. C., R. S. Gennari, G. E. Dahl, and A. De Vries. 2016. Economic feasibility of cooling dry cows across the united states. J. Dairy Sci. 99:9931-9941.

- Hillman, P. E., C. N. Lee, and S. T. Willard. 2005. Thermoregulatory responses associated with lying and standing in heat-stressed dairy cows. Trans. ASAE 48:795-801.

- Kadzere, C. T., M. R. Murphy, N. Silanikove, and E. Maltz. 2002. Heat stress in lactating dairy cows: A review. Livest. Prod. Sci. 77:59-91.

- Lambertz, C., C. Sanker, and M. Gauly. 2014. Climatic effects on milk production traits and somatic cell score in lactating Holstein-Friesian cows in different housing systems. J. Dairy Sci. 97:319-329.

- Overton, M. W., W. M. Sischo, G. D. Temple, and D. A. Moore. 2002. Using time-lapse video photography to assess dairy cattle lying behavior in a free-stall barn. J. Dairy Sci. 85:2407-2413.

- Polsky, L. and M. A. G. von Keyserlingk. 2017. Invited review: Effects of heat stress on dairy cattle welfare. J. Dairy Sci. 100:8645-8657.

- Reuscher, K.J., N.B. Cooki, T.E. da Silva, M.R. Mondaca, K.M. Luchterhand, and J.M.C. Van Os. 2023. Effect of different air speeds at cow resting height in freestalls on heat stress responses and resting behavior in lactating cows in Wisconsin. J. Dairy Sci. 106:9552-9567.

- Reuscher, K. J., N.B. Cook, C.E. Halbach, M.R. Mondaca, and J.M.C. Van Os. 2024. Consistent stalls air speeds in commercial dairy farms are associated with less variability in cow lying times. Front. Anim. Sci. 5:1422937.

- Schütz, K. E., A. R. Rogers, Y. A. Poulouin, N. R. Cox, and C. B. Tucker. 2010. The amount of shade influences the behavior and physiology of dairy cattle. J. Dairy Sci. 93:125–133.

- Silanikove, N. 2000. Effects of heat stress on the welfare of extensively managed domestic ruminants. Livest. Prod. Sci. 67:1–18.

- Spiers, D. E., J. N. Spain, J. D. Sampson, and R. P. Rhoads. 2004. Use of physiological parameters to predict milk yield and feed intake in heat-stressed dairy cows. J. Therm. Biol. 29:759–764.

- Stull, C. L., L. L. McV. Messam, C. A. Collar, N. G. Peterson, A. R. Castillo, B. A. Reed, K. L. Andersen, and W. R. VerBoort. 2008. Precipitation and temperature effects on mortality and lactation parameters of dairy cattle in California. J. Dairy Sci. 91:4579-4591.

- Tresoldi, G., K. E. Schütz, and C. B. Tucker. 2016. Assessing heat load in drylot dairy cattle: Refining on-farm sampling methodology. J. Dairy Sci. 99:8970-8980.

- Van Os, J. M. C. 2019. Considerations for cooling dairy cows with water. Vet. Clin. N. Am. 35:157-173.

- Vitali, A., M. Segnalini, L. Bertocchi, U. Bernabucci, A. Nardone, and N. Lacetera. 2009. Seasonal pattern of mortality and relationships between mortality and temperature-humidity index in dairy cows. J. Dairy Sci. 92:3781-3790.

- Webster, J. 1993. Environmental physiology and behaviour. In: Understanding the dairy cow, ed. J. Webster. Blackwell Scientific Publications, Boston, MA.

- West, J. W., B. G. Mullinix, and J. K. Bernard. 2003. Effects of hot, humid weather on milk temperature, dry matter intake, and milk yield of lactating dairy cows. J. Dairy Sci. 86:232-242.

Download Article

Animal Handling During Heat Stress

Animal Handling During Heat Stress Heat Stress Abatement in Dairy Facilities

Heat Stress Abatement in Dairy Facilities Effects of Heat Stress on Dairy Reproduction

Effects of Heat Stress on Dairy Reproduction Dry Cow Heat Stress Management

Dry Cow Heat Stress Management