Hutches are commonly used for calf housing. The use of individual hutches is beneficial in preventing the spread of diseases, particularly as young animals are highly vulnerable to infections. However, there are challenges in using hutches in cold climates, such as protecting calves from prevailing winds while ensuring adequate air quality inside. An alternative to this is indoor calf housing, where renovated old barns can be utilized, taking advantage of the existing structure. Adapting an old building to house calves involves several steps:

Adaption steps:

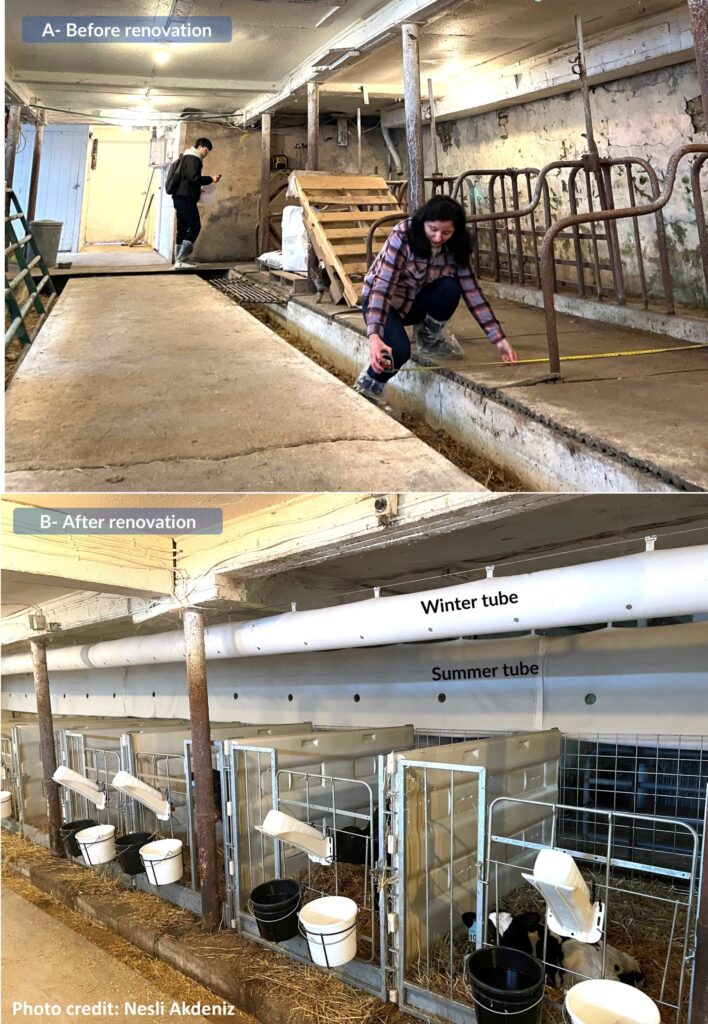

- Assessment of space and barn condition: Evaluate the barn’s structural integrity, focusing on the roof, walls, and flooring (see Figure 1A). Create a detailed floor plan of the barn, including all connected rooms, any obstructions, and the exact dimensions of the barn. Utilize this floor plan to design calf pen arrangements that facilitate easy access for feeding, bedding, manure removal, and treatment. Also, note the ceiling height, positioning of beams, and location of overhead doors, which are critical factors while planning the installation of aeration fans and ducts.

- Placing pens: Plan on removing stalls. Calves are ideally housed in pens. The use of solid dividers between calf pens restricts face-to-face contact and assists in reducing drafts. Having the front and back panels open allows air exchange within the pens. The minimum recommended pen size is 4 ft (W) × 7 or 8 ft (L).

- Flooring: Clean manure gutters thoroughly. Consider filling gutters to provide a uniform floor surface and to conveniently clean with a front-end loader.

- Isolation pens: Plan to have separate pens for calves needing special attention.

- Ventilation and temperature control: Good ventilation is vital for calf health. Sufficient air exchange is necessary to reduce humidity and pathogens while preventing drafts that could adversely affect the calves’ health. Plan on making necessary changes, such as replacing old fans or adding new fans and vents.

Ventilation requirements

The ventilation requirements of calf buildings vary between the summer and winter seasons. In summer, the ventilation system is designed to remove excess heat and moisture from the building to maintain a comfortable temperature for the animals. In winter, the goal is to manage heat loss while still providing adequate air exchange to maintain air quality. The ideal temperature for dairy calves ranges between 50 and 78°F for newborns and between 32°F and 73°F for one-month-old calves. In naturally ventilated calf barns, producers close the curtain sidewalls to create a draft-free environment during cold weather.

Figure 1. Renovating a 30-head tie-stall barn to house calves up to 8 weeks of age.

Even though naturally ventilated barns may have good air quality, calf pens may have poor air exchange. As calves do not produce much heat, thermal buoyancy is limited in calf pens, resulting in poorly ventilated micro-environments within calf pens. This has been linked to an increased risk of bovine respiratory disease (BRD).

In mechanically ventilated buildings, when temperatures drop below 50°F, air exchange rates are lowered to maintain a comfortable temperature for the calves. The recommended minimal cold weather ventilation rate is 20 cfm (34 m3/h) of air per calf. This requires an air inlet area of approximately 0.05 ft2 (0.005 m2) per calf. However, providing fresh air through such a small air inlet results in difficulty distributing it evenly throughout the barn, which often leads to poor air quality within the pens. As a result, it is a delicate balance between ensuring the thermal comfort of the calves while also maintaining a good pen environment.

Positive pressure tube ventilation

One commonly used ventilation system for calf barns is the positive pressure ventilation tube (PPTV). The system consists of a long tube extending along the internal length of the barn, with a wall-mounted fan at one end. This fan draws fresh outside air into the barn. The tube has equally spaced holes. The incoming air pressurizes the tube, blowing air out of each hole to evenly distribute it throughout the barn. The whole system is designed to deliver fresh air to the vicinity of the calf while ensuring slow airspeed at the calf level to avoid drafts.

The diameter and spacing of the holes are specifically designed for each system. An example of PPTV is shown in Figure 1B. In the front, the winter tube, which is 9 inches in diameter, can be seen inflated, while the larger summer tube, measuring 26 inches in diameter, is seen uninflated in the back. When barn temperatures fall below 68°F, the winter fans begin operating, providing 4-6 air exchanges per hour. Conversely, when temperatures rise above 68°F, the summer fans are activated, ensuring a minimum of 40 air exchanges per hour. On particularly warm days, both winter and summer fans can be manually turned on for enhanced ventilation. The location of the tubes, as well as the number and angle of the holes, should be designed to ensure each pen receives fresh air and the directed air reaches the pens at a height of 4 feet above the floor, aligning with the height of standing calves.

Positive pressure tube fans should draw fresh air from the outside. If there is an adjacent barn where older animals are housed, the air duct should not draw air from this barn but should instead pull fresh air from outside. Additionally, provisions must be made for air to exit the barn to achieve proper air exchange. This can be implemented in various ways, such as leaving windows and/or doors open.

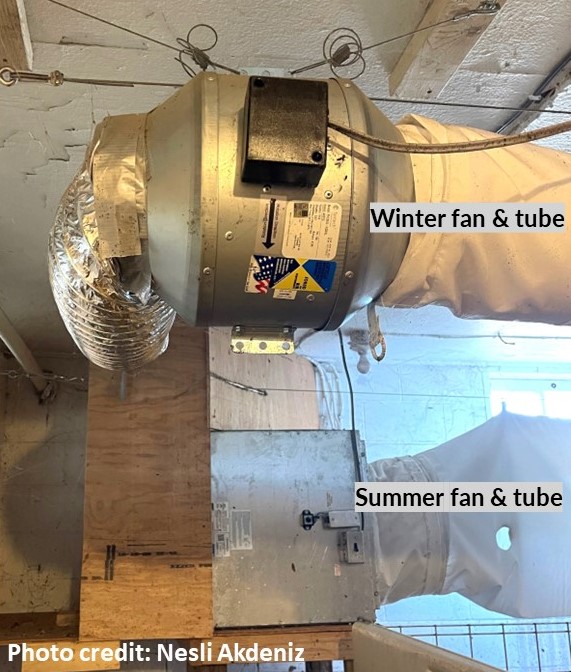

Figure 2. Air inlets and fans of the PPTV

Figure 2 illustrates the air inlets used in the barn of Figure 1. The ventilation system comprises DuctSox fabric tube paired with a Greenheck inlet fan for summer ventilation and a Fantech inline fan for winter ventilation. The plywood duct provides access to the outside. This is the tube system for the west side of the barn. A similar system is installed on the east side, totaling four inline fans. The estimated cost of the design is $12,000, excluding labor costs.

Depending on the level of maintenance provided, the system is expected to have a lifespan of 7-10 years. Regular cleaning of the fans is crucial to prevent any reduction in their efficiency. Additionally, it is important to ensure that no dust or mold accumulates in the fabric tube, as this can affect the calves’ health and the system’s longevity. The tube should be checked regularly for any visible signs of damage or wear and replaced as needed.

The UW-Madison School of Veterinary Medicine’s Dairyland Initiative has developed a spreadsheet for use in designing PPTV systems. They maintain a list of certified users of this spreadsheet, which can be accessed at https://thedairylandinitiative.vetmed.wisc.edu/professionals/industry-contacts/.

Summary

Renovating tie-stall barns, which are no longer in use, to house calves is an option. After determining the number of pens that can be accommodated, the most important step is to upgrade the ventilation system to meet the specific needs of the calves. PPTV can be used either as supplementary ventilation to the existing natural or mechanical ventilation systems.

For more information

Akdeniz, N., McCarville, J., Schlesser, H., Seefeldt, L., Sterry, R. 2023. Ventilation in Dairy Buildings. Dairy, UW-Madison Extension. Online available at https://dairy.extension.wisc.edu/articles/ventilation-in-dairy-buildings/ (access date 11-17-2023).

The Dairyland Initiative Website (access date 11-17-2023)

Midwest Plan Service (MWPS 32)- Mechanical Ventilating Systems for Livestock Housing.

Nordlund, K.V., and Halbach, C.E. 2019. Calf barn design to optimize health and ease of management. Veterinary Clinics of North America: Food Animal Practice, 35(1) 29-45. https://doi.org/10.1016/j.cvfa.2018.10.002

This factsheet was reviewed by Brian Holmes, Professor Emeritus, Biological Systems Engineering, UW-Madison and Courtney Halbach, Outreach Specialist, the Dairyland Initiative, UW-Madison.

We greatly acknowledge Jill Berg and Paul Berg for allowing us to visit their farm and for sharing their experience with us.

For questions or comments, please contact Nesli Akdeniz at nesli@wisc.edu

Last updated on December 11, 2023.

Ventilation Fan Noise in Dairy Buildings

Ventilation Fan Noise in Dairy Buildings Build Your Foundation on High Fertility

Build Your Foundation on High Fertility Target age and weight when breeding dairy heifers

Target age and weight when breeding dairy heifers Variability in Your Dairy’s Data: Look Beyond the Average

Variability in Your Dairy’s Data: Look Beyond the Average