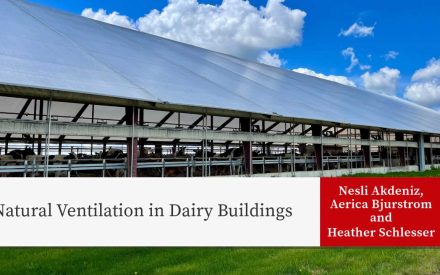

Listen to this article

Introduction

Dairy cows are more sensitive to heat than many people realize. While humans may feel comfortable in temperatures ranging from 70ºF and beyond, dairy cows begin to experience heat stress at this point. This is because a cow’s thermal neutral zone—the temperature range in which they do not have to expend extra energy to stay warm or cool—is between 40ºF and 70ºF. A significant factor contributing to their sensitivity is the high metabolic heat they generate; a high-producing dairy cow can produce over 6,000 BTUs of heat per hour, making it challenging for them to stay cool as temperatures rise.

When considering new barn options, some owners want all their animals under one roof; a cross-ventilated barn is ideal. Cross-ventilation is a mechanical ventilation system where air flows horizontally across the barn, from one long wall to the opposite wall, driven by fans and inlets, not by natural wind. Air moves perpendicularly to feed lanes and parallel to cows resting in stalls or eating at the bunk. The cross-ventilated barn design allows medium and large herds to be housed in one building while maintaining a consistent temperature for all animals without pockets of warm or cold spaces.

Design

A cross-ventilated barn has fans along one sidewall pulling fresh air through inlets on the opposite wall. The barn is wide, typically with 8-16 (or more) rows. Curtains or cooling pads are installed on the inlet side, usually on the south side of an east-west orientated barn. Baffle curtains or walls direct airflow at the cow level for maximum cooling. A continuous bank of large-capacity exhaust fans is placed on the opposite side wall to draw fresh air across the barn from the inlets.

Inlets

The inlets have split curtains: a larger bottom opening and a smaller top opening. In summer, the bottom curtain is open to allow cool air to enter low and flow over the cows for maximum cooling.

In winter, the bottom curtain is closed. Only the top curtain lets in a smaller, higher airstream, which mixes with warmer air to reduce drafts.

Evaporative cooling pads can be used with inlets in hot weather (Figure 1). Evaporative cooling pads are commonly used with cross-ventilated barns to reduce heat stress on livestock, particularly in hot and dry climates. These pads are installed at the air intake side of the barn and work by pulling air through a saturated medium, which lowers the air temperature through evaporation. These pads are made of a permeable material kept wet with water as air is drawn through the pads, water evaporates, absorbing heat and lowering the air temperature. This helps to create a more comfortable environment for the animals.

(Photo: Aerica Bjurstrom)

Baffles

Baffles are crucial in cross-ventilated barns to direct airflow effectively, ensuring cool air reaches the animals in the resting areas. Without baffles, air might circulate from floor to ceiling, reducing the cooling effect, especially during hot weather.

In a cross-ventilated barn, baffles are placed longitudinally within the barn structure, often over or near the stalls, to redirect airflow and increase air speed in the resting area. They are hung from the ceiling or mounted on the walls, usually extending toward the floor. The lower edge of the baffle is positioned at least 6 feet above the floor to allow for animal movement.

(Photo: Aerica Bjurstrom)

Optimal baffle placement is barn-dependent. Baffles are ideally located over the middle of a head-to-head row of stalls and influence airflow over only 10 to 15 feet (Figure 2). Placing the baffle at the edge of the stall platform closest to the inlets is an alternative, but steps must be taken to protect the baffle from machinery used in the barn. Approximately 12 inches of open space should be left open at the top of the baffle to allow air to bleed over the top, reducing condensation and stale air build-up behind the baffle.

Baffles can be constructed from rigid materials like metal or flexible materials like canvas or fabric. Baffles made from flexible materials can be retractable, allowing for adjustments to airflow in different seasons. While some fans will continuously run during cold weather months, retractable baffles can be pulled up when rapid airflow is not needed over the cows for cooling purposes.

Fans

For most cross-ventilated barns, 52” to 54” diameter fans are recommended, as they offer a good balance of airflow and efficiency. While larger fans can move more air, they must be appropriately matched to the barn’s width and the desired airspeed to avoid inefficiencies. Regarding ventilation performance, the recommended air exchange rate is 40–60 air changes per hour during hot weather, and roughly 1,000 to 1,500 CFM (cubic feet per minute) of airflow per cow, depending on the climate and barn layout. For example, a 100′ x 400′ barn might require between 24 and 36 fans, depending on the fan model and spacing. Air velocity should be targeted at 2 to 5 mph over the cows—this is enough to provide cooling without causing drafts or stress. To improve system efficiency and performance, installing backdraft shutters or louvers is helpful to prevent air from re-entering through idle fans. During colder months, fan covers or fans with automatic shutters can reduce heat loss. Additionally, variable speed drives or automated environmental controls that respond to temperature and humidity sensors can significantly improve energy efficiency and animal comfort.

Design Considerations

Cross-ventilated barns typically have a much lower roof pitch than naturally ventilated ones. Cross-ventilated barns often use a roof slope of 0.5 to 1 in 12, while naturally ventilated barns commonly utilize a 3/12 to 4/12 pitch. This lower pitch in cross-ventilated barns is achieved to reduce the overall height of the barn, especially in wide-body designs, while still allowing for adequate airflow.

Barn orientation and site layout

Barn orientation significantly impacts the effectiveness of cross-ventilation. Ideally, a barn should be oriented east-west to maximize airflow from prevailing winds, which are from the west in North America. This orientation allows the barn to take advantage of natural breezes for cooling, helping to keep animals comfortable and the barn environment healthy.

Understanding the prevailing wind direction where the barn will be built is crucial for optimizing barn orientation. Ensure that the barn is not located where it will be blocked by other buildings or trees, which can reduce airflow. When deciding on site location, consider slope and terrain, which can influence airflow patterns.

Barn shape

Low-profile cross-ventilated barns are square or rectangular. The low-profile roof allows efficient air movement through the building, minimizing vertical air stratification. While naturally ventilated barns rely on steep roofs to vent air through the top ridge like a chimney, cross-ventilated barns mechanically move air rapidly through the building.

A disadvantage of a low-profile roof in northern climates is the risk of heavy snow load, which can cause damage or run the risk of collapse. Snow load should be considered when designing a cross-ventilated building.

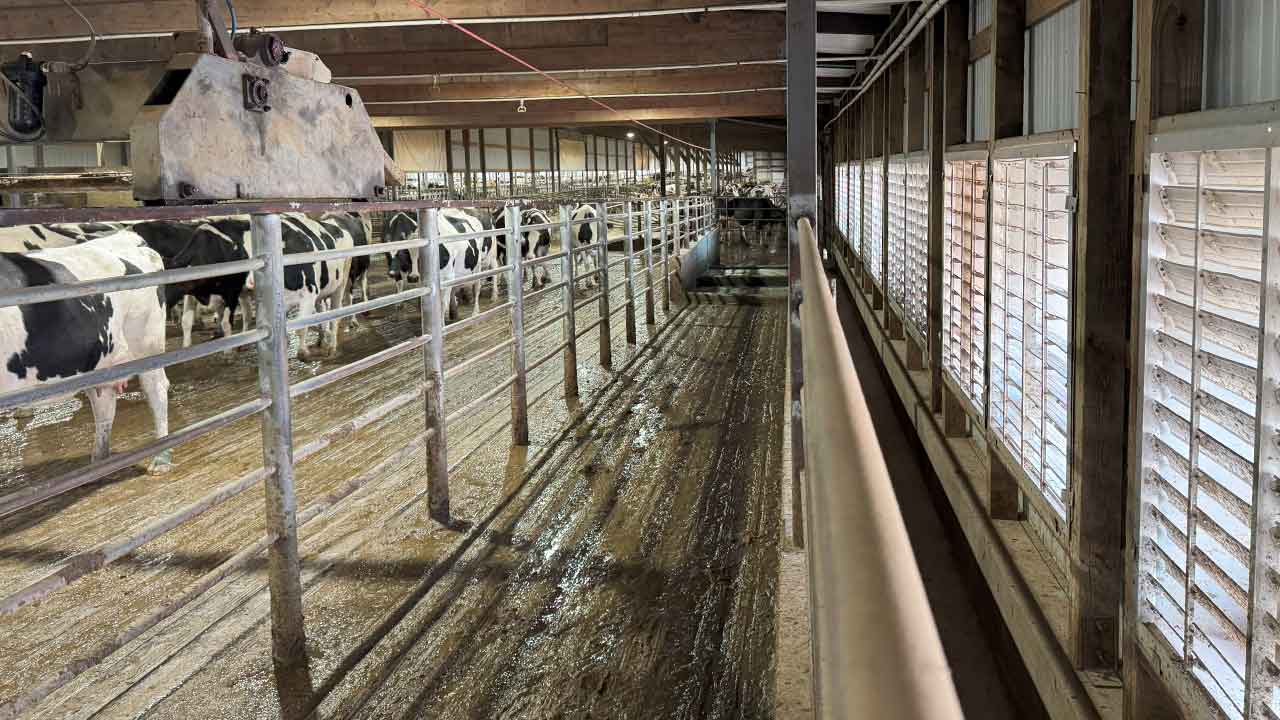

Holding pen design

Cows in holding pens typically have 15 square feet per animal, a vast difference from their home pen, which can be 80-120 square feet per cow. Cooling needs should be considered in the milking parlor holding pen (Figure 3). Research has shown that, without cooling, a cow’s body temperature increases by 3°F within 20 minutes after entering the holding pen. When a cooling system, including fans, was installed, the cow’s body temperature lowered by 3.5°F while the cows were in the holding pen.

(Photo: Aerica Bjurstrom)

Animal Health

Cross-ventilated barns offer advantages for animals because continuous airflow removes heat, humidity, dust, and gases like ammonia. Continuous airflow also disrupts flying insects such as flies and mosquitoes, which can carry diseases and pester cows.

Better temperature control in cross-ventilated barns is an advantage over other barn styles. Fans and curtain systems maintain a stable climate regardless of season, reducing heat stress in the summer and cold drafts in the winter. Another health advantage of cows is consistent airflow, which keeps core body temperature consistent. More consistent conditions lead to better resting behavior and lying time.

A consistent environment and a comfortable, low-stress cow result in better feed intake, reproduction, better behavior, and reduced disease risk. Additionally, the work environment is also comfortable for workers.

Fan maintenance

Consistent upkeep of ventilation fans is critical to ensuring adequate airflow in dairy facilities. Even though eliminating dust buildup is unrealistic, allowing it to accumulate, especially on shutters, can drastically reduce fan performance, with studies indicating efficiency losses between 10% and 40%. Fans should be cleaned regularly and thoroughly to keep airflow strong and energy use low. It’s especially important to conduct a full maintenance check before hot weather arrives (Figure 4). Before servicing, always disconnect the power source, and inspect components like belts, pulleys, and fasteners for wear, damage, or looseness. Lubricate moving parts such as pivot points as needed to maintain smooth operation and

extend equipment lifespan.

Lighting

Cross-ventilated barns are built to limit the amount of natural light that comes in, which helps keep the barn cooler. This also gives farmers better control over the lighting inside the barn, allowing them to use long-day lighting (LDL) strategies. By adjusting the light cycle, LDL helps boost melatonin levels in the cows, which then increases a hormone called IGF-1, essential for milk production.

On the flip side, shorter daylight periods can be helpful for dry cows. When these cows are kept in an environment with just 8 hours of light and 16 hours of darkness, they tend to eat more and may produce more milk in their subsequent lactation.

In cross-ventilated barns, almost everything gets done under artificial light. That makes good lighting a top priority—not just for the cows, but also for the people who spend their day working with the animals.

Electricity Use

Electricity use in cross-ventilated dairy barns is significantly higher than in naturally ventilated barns due to their reliance on mechanical systems for air movement. The primary source of electricity consumption is the exhaust fans, which are typically the most significant energy draw. Using the recommended high-capacity 52″–54″ fans, may run continuously during hot weather to maintain the recommended 40–60 air changes per hour. For example, a 1 HP fan consumes about 0.75 kWh per hour, meaning that 24 nonstop fans could consume around 432 kWh per day. Variable frequency drives (VFDs) and automated controls are commonly used to modulate fan speed based on temperature, humidity, or wind speed, reducing energy use during cooler periods. Motorized curtain systems and actuators, which adjust airflow through inlet openings, also consume electricity, albeit at lower levels. Lighting also contributes to energy demand, particularly in large barns that require ample illumination during winter or around-the-clock operations, though using LED lighting can help mitigate this. Efficiency can be improved by using high-efficiency fans like those with EC motors, integrating zoning and environmental sensors to optimize fan operation, and applying scheduled ventilation logic to reduce usage during shoulder seasons. Regarding actual consumption, a 100′ x 400′ barn with 24–36 fans may use approximately 400–700 kWh daily in summer, translating to 12,000–21,000 kWh monthly, or $1,200–$2,100 depending on electricity rates. In winter, usage drops significantly, often falling to 10–20% of summer levels as the curtain systems take over more of the ventilation function.

(Photo: Aerica Bjurstrom)

Summary

Cross-ventilated barns offer a modern, effective solution to managing the thermal sensitivity of dairy cows, particularly in the face of rising temperatures and heat stress challenges. By utilizing a well-designed system of fans, inlets, baffles, and environmental controls, these barns maintain consistent air flow and temperature regulation throughout the year, improving animal comfort and productivity. While they require greater electricity than naturally ventilated barns, the benefits in cow health, milk production, and worker comfort make them a worthwhile investment for many dairy operations. Cross-ventilated barns can play a vital role in sustaining high-performance dairy herds while supporting long-term operational efficiency with proper orientation, design, maintenance, and energy-efficient upgrades.

Authors

Aerica Bjurstrom

Regional Dairy Educator – Aerica’s work focuses on herd health and animal welfare. She also has a strong background in meat quality and has done programming in market cow carcass quality.

Neslihan Akdeniz

Livestock Controlled Environments Extension Specialist, Assistant Professor– Mainly focusing on controlled environments for livestock production, also interested in nutrient management and indoor plant-growing facilities.

Heather Schlesser

County Dairy Educator – Heather Schlesser is an Agriculture Educator in Marathon County. Heather’s research and outreach have included the use of current technology to enhance farm profitability and sustainability. Her current projects include the Animal Wellbeing Conference, the Midwest Manure Summit, Beef Quality Assurance, financial programming, and teaching farmers throughout the Midwest how to breed their own cattle.

Acknowledgement

We are grateful for the Wisconsin Idea Collaboration grant provided by UW-Madison Extension (AAM9947).

References

- Modeled Construction and Operating Costs of Different Ventilation Systems for Lactating Dairy Cows. Mondaca, M. R., & Cook, N. B. (2019). https://www.sciencedirect.com/science/article/pii/S002203021830972X

- PubMed Article: Smith, J. A., & Doe, R. L. (2023). Evaluation of low-profile cross-ventilated systems in dairy barns. Journal of Dairy Science, 106(7), 4567–4578. https://pubmed.ncbi.nlm.nih.gov/37474668/

- The Dairyland Initiative. (n.d.). Ventilation and heat abatement. University of Wisconsin–Madison School of Veterinary Medicine.

https://www.sciencedirect.com/science/article/pii/S002203021830972X - YouTube Video: University of Wisconsin-Madison Extension. (2021, March 15). Cross-ventilated barn design for dairy cows [Video]. YouTube. https://www.youtube.com/watch?v=tPzfOMbKxLo

- Ventilation and Heat Abatement: The Dairyland Initiative. (n.d.). Ventilation and heat abatement. School of Veterinary Medicine, University of Wisconsin–Madison. https://thedairylandinitiative.vetmed.wisc.edu/home/housing-module/adult-cow-housing/ventilation-and-heat-abatement/

- Akdeniz, N., McCarville, J., Schlesser, H., Seefeldt, L., & Sterry, R. (n.d.). Ventilation in dairy buildings. University of Wisconsin–Madison Division of Extension. https://dairy.extension.wisc.edu/articles/ventilation-in-dairy-buildings/

Download Article

Air Quality in Calf Housing

Air Quality in Calf Housing Natural Ventilation in Dairy Buildings

Natural Ventilation in Dairy Buildings Animal Handling During Heat Stress

Animal Handling During Heat Stress Heat Stress Abatement in Dairy Facilities

Heat Stress Abatement in Dairy Facilities